MORX VDS Approved CO₂ fire suppression total flooding system is specifically designed to combat Class B and Class C fires involving flammable liquids and gases, as well as energized electrical equipment.

CO₂ is a non-conductive agent that is a highly effective for fire protection solution, designed to rapidly suppress fires in enclosed areas by displacing oxygen and interrupting the chemical reaction of combustion. Utilizing carbon dioxide as the extinguishing agent, the system discharges CO₂ into a protected enclosure, reducing the oxygen concentration to a level below that required to sustain a fire.

This type of system is commonly used for enclosed, unoccupied, or limited-occupancy spaces where water-based or foam suppression is impractical or could cause damage, such as electrical rooms, data centers, engine compartments, and industrial machinery spaces.

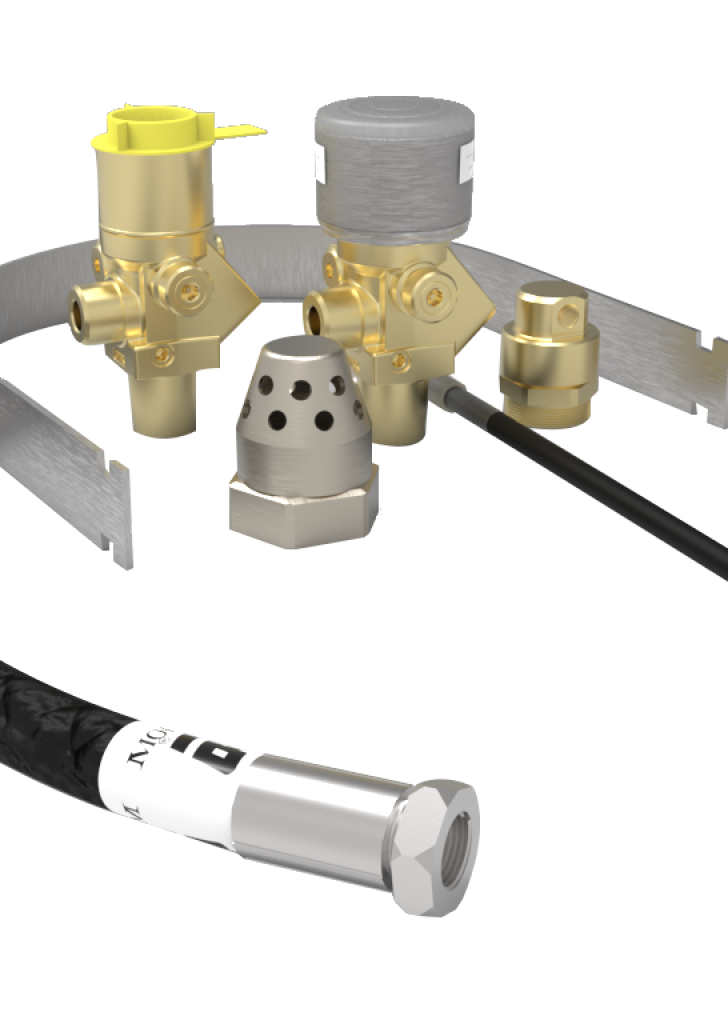

Total flooding systems are engineered for fast response and typically include detection, control panels, storage cylinders, and a network of piping and discharge nozzles. Due to the asphyxiation risk associated with high CO₂ concentrations, these systems are designed with safety interlocks, warning alarms, time delays, and evacuation procedures to ensure personnel safety prior to discharge.

Types of Fires for CO₂ Fire Suppression Systems:

CO₂ fire suppression systems are primarily used for Class B and Class C fires:

• Class B Fires: Flammable liquids and gases such as gasoline, oil, solvents, and propane.

• Class C Fires: Fires involving energized electrical equipment, such as control panels, switch-gear, and server racks.

CO₂ is non-conductive, leaves no residue, and is effective in areas where water or foam could damage sensitive equipment or processes.

Typical Applications:

CO₂ total flooding systems are ideal for protecting enclosed, unoccupied or limited-occupancy spaces. Common applications include:

• Power generation facilities (turbine enclosures, generator rooms)

• Electrical switch-gear and transformer rooms

• Data centers and server rooms

• Marine engine rooms and machinery spaces

• Industrial paint spray booths

• Printing and paper processing areas

• Chemical processing facilities

• Underground cable tunnels

as CO₂ displaces oxygen, safety protocols such as per-discharge alarms, time delays, and interlock systems are critical in all applications to protect personnel.